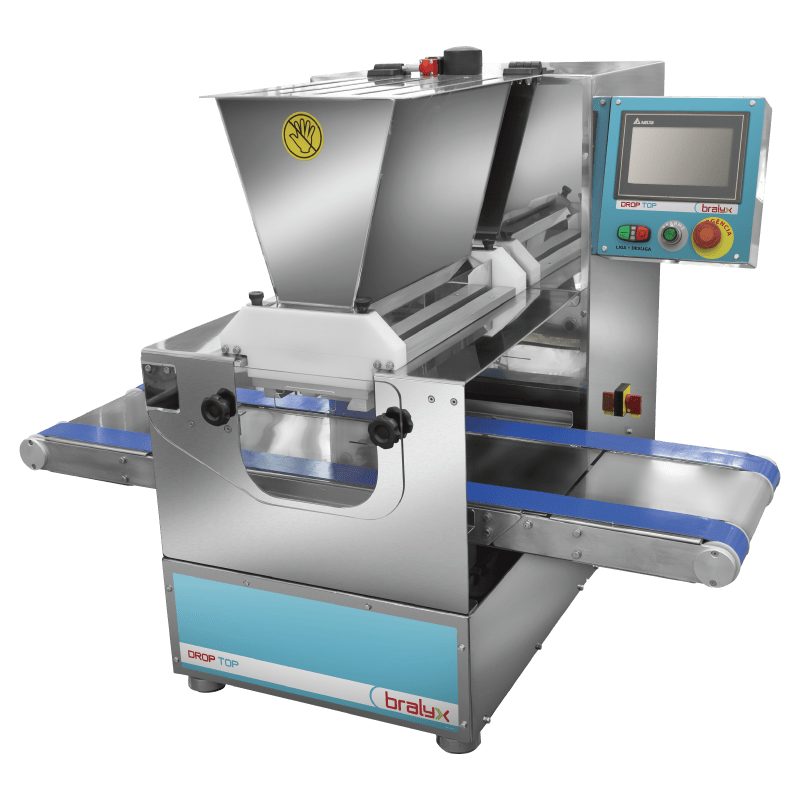

DROP TOP 400.450 PLUS

Request a quote

Confectionery machine Drop Top 400/450.

Drop Top 400/450 is a complete and efficient confectionery and cookie (biscuit) machine manufactured by Bralyx with the latest technology and high automation. It is composed by 3 systems:

- Depositor (dropping)

- Dosing

- Wire cutting

Drop Top is ideal for bakers, confectioners, cake shopers, caterers and hoteliers who are looking for enhanced productivity and increased variety in the baked goods.

Diversify your production with precision, standardization and economy. Main features of confectionery machine Drop Top 400/450:

- Depositing with rotary system for dense dough. Ideal for production of petit fours/ shortbread biscuits/ donuts/ choux bun (profiteroles/ eclairs) / etc

- Wire cutting system for hard dough. Ideal for the production of various types of cookies/ cheese bread/ etc

- Dosing system (stationary system) for semi-liquid and fluid dough. Ideal for the production of muffins/ cupcakes/ macarons/ meringues/ lady fingers/ sponge cake/ swiis roll/ etc

- User-friendly interface. Simple and uncomplicated operation

- 7’ touch screen panel – Stores up to 100 recipes for quick recall in several languages (English/ Spanish/ Portuguese/ Arabian)

- Provides total control of product weight, size, height, length and shape

- Developed with encoder system which measures the distance between products on the tray

- Interchangeable accessories

- Structure and heads in STAINLESS STEEL .

- Quick cleaning: easily removable hopper, roller and nozzles

- BRALYX DIFFERENTIAL: 1 year total warranty and technical support

Components of the Confectionery machine Drop Top 400/450:

- Roller heads for fluid, dense and hard dough

- Stationary and rotary molds

- Cutter set

- Cutting molds (Check the available options or customize your own)

- Smooth and Star shape off-center nozzles (bronze)

- Smooth and Star shape nozzles (plastic)

- Optionals: Check all avaiable acessories with our sales team

Watch DROP TOP PLUS

Technical Specifications

PRODUCTIVE CAPACITY:

- WIRE CUTTING: up to 390kg/h

- STATIONARY SYSTEM DOSAGE: up to 107kg/h

- ROTARY SYSTEM DOSAGE : up to 103kg/h

- LONG STATIONARY SYSTEM DOSAGE: up to 49.5 kg/h (up to 10cm long product)

- CAKE DOSAGE: 414 kg/h

- Speed: 20/25 rows/min.

- Power input: 0,6kW (1CV) – 220V – Single-phase

- Machine dimension (Width x Length x Height): 987 x 1124 x 919mm / (38,8” x 44,2” x 36,1”)

- Tray dimension (Width x Length x Height): 400-450 x 600 x 11,5 mm (15,7” – 17,7” x 23,6” x 0,45”)

- Dough head capacity: up to 20kg (depends on the type of the dough)

- Net weight: aprox. 136kg/ 299,8lb

SAFETY CERTIFICATION:

![]()