Working with production of savory or sweet foods in large amounts, keeping the quality standard, is a true challenge, even for those who are in this area for a long time. To stores’ owners, food manufacturers or people who intend to open a business in this branch, having control over the production process is necessary for three simple reasons:

- to deliver a food with the same quality always;

- to provide products with same weight and characteristics which were negotiated and promised to customers and resellers;

- to avoid unnecessary waste of ingredients for the production.

Many factors can affect and modify the product’s flavor or size. The incorrect weighing of the ingredients, the exchange of providers, or the manual molding are some examples. To avoid these unwanted changes, it’s necessary to follow the planning and the production routine rightly.

The main tip to follow this planning is to analyze and register each step of the established routine. If you accomplish this control, you’ll be able to evaluate how your food production can get better, and it’ll be easier for you to pass everything that must be done along all the involved ones at the production.

How to create and control your food production system

Each one has one’s recipe and a different way of making savory or sweet foods, but this way must be registered. When you have written down everything you do, well detailed, you are creating a PRODUCTION SYSTEM.

Creating a system is fundamental for you to be able to control what is being done and evaluate what can be improved, and one thing is right: it’s always possible to improve! But if you can’t see clearly HOW the work is being done, you aren’t able to improve WHAT is being done.

To start, it’s necessary to draw a flowchart of all the productive process, since de beginning: how the merchandise is stored, passing through the production itself, up to storage, packaging and distribution. This way, you will notice whether you can buy a smaller number of products, for example, or realize that disposing the products in a certain way on the bench makes production more agile.

Doing also the financial management is fundamental, in this part you’ll understand how you should direct your business rightly. There are several apps and spreadsheets which help you in financial management, but don’t stick to it, if you find it difficult. Pencil and notebook, with everything that comes in and out, can run the errand, at least at the beginning.

So, the answers you can get if you register your work process are many. At the beginning it can be tiring, but do not get discouraged. If it’s possible, ask for someone’s help, mainly at the production, because sometimes we do things so automatically that we don’t even think about registering them.

Poduction stages

Following the production stages is not very different from the accompaniment of a recipe. Accompanying these steps can be fundamental for the success of controlling your food production:

Choice of ingredients, providers and storage

Look for the best ingredients with providers who offer fair prices. Have a suitable space to store perishable and non-perishable foods.

Weighing of ingredients for dough and filling

The quantity variation of a flavoring or flour can change the flavor or the texture of the filling or the dough.

Preparation of the dough and filling

Being careful with the time of the dough cooking, during its preparing, using a clock or a timer to establish and register the preparing time of each stage. This orientation also goes for cooked fillings, and the raw ones, such as registering the time spent for cutting foods like ham and cheese.

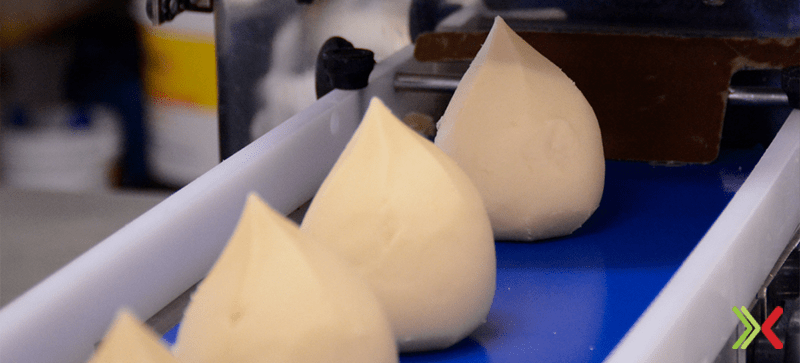

Savory foods molding

This is one of the most delicate stages to reach the standard, because it’s the one that most interferes in the visual. Equal savory foods with different formats, specially when they are disposed side by side, don’t cause a good impression. Using savory foods machines for the molding gets the standardization of the formats better.

Freeze, pack and store

After the savory foods are ready, it’s time to freeze them (the most indicated temperature is -10°C – or 14°F), put them in suitable packaging – remember of tagging them with information about the production and valid dates – and then store them under a temperature of -10°C (14°F).

It’s extremely recommended planning these stages before their execution. To confirm the planning in practice, do tests on a small quantity, verifying if everything is happening as expected.

Infrastructure for savory food production

For the savory foods production with more quality, the savory foods machines can be great allies. Scales, freezer and machines for preparing the dough and filling and breading the savory foods too. These machines help the maintenance of the expected standard, once, mostly, they offer greater accuracy than the manual working. Therefore, it’s always a good long-term investment.

When it’s about food, it’s fundamental to care about hygiene, preserving the consumers’ health. For that, the entrepreneur in the food industry needs to be aware of the hygiene in the places of storage and production, always requiring the involved ones the maximum possible care. Accomplishing the cleaning of machinery periodically also prevents contamination of foods.

Another tip is to guide the resellers and consumers about how to handle the savory foods in a hygienic way. Sometimes, the improper handling may contaminate or damage the savory food, causing bad impression and also problems of health to the final consumer.

Aware of all these details, the manufacturer is able to reach de adequate control on the savory foods production, keeping the standard expected by him and by the customers.

DO YOU WANT LEARN MORE ABOUT FOOD PROCESSING MACHINES FOR FOOD BUSINESS? CLICK HERE AND GET IN TOUCH WITH OUR SALES TEAM!

No products in the cart.

No products in the cart.