Shop by Categories

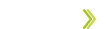

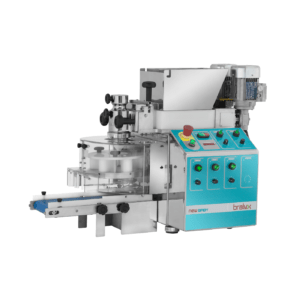

TUBO ITA

Exclusive pressure dough feeding system that keeps the texture of your product, such as grains, cereals and nuts maintaining them whole and unbroken.

Produce savory and sweet products with our industrial forming and encrusting machine TUBO ITA, designed for long working hours, perfect for your production!

TUBO ITA is a Industrial Forming and Encrusting Machine designed for industrial productions who prioritize the quality of their products.

Produce a wide range of filled and non-filled products, such as gnocci, arancini, arancini palina, supplì, meatballs, polpetone, croquettes, cookies, kibbeh and a lot more.

Designed for rigorous producers who wish to standardize and industrialize their production, keeping the texture and quality of their products unchanged, TUBO ITA has an exclusive pressure dough feeding system that allows you to maintain the texture of your dough, regardless of whether it is made with grain, cereals or nuts, keeping the grains whole and unbroken.

Reduce the wheigh variation of your products with the exclusive system of our machine, producing from 7g up to 220g* at a pace from 1.150 up to 5.000 pieces per hour¹.

Due to its more powerful engines, the TUBO ITA is capable of working for longer hours, keeping up with the pace of industrial produtions, without compromising the machine’s operation.

Analog controls for precise adjustments and better visibility of the process, it is also Stainless steel constructed, for enhanced durability, resistance, and hygiene.

Providing the best that the BRALYX quality standart can offer, the TUBO IT complies with stringent international safety standards, including European (CE) certification.

With its 1-year full warranty*, training*, and technical support provided, our TUBO ITA Forming Machines is the perfect choice for expanding your production to a new level.*Consult the sales department for conditions.

Enhance your production further with our Planetary Cooking Mixers, equipped with exclusive bowls and beaters, designed specifically for your sweet-making needs!

HOURLY PRODUCTION¹:

- up to 5000 pcs (7 -30g / 0,24 –0,55oz)

- up to 1150 pcs (180 /220g /6,35/7,76oz)

PRODUCT SIZE²: from 7 to 220g (from 0,24oz to 7,74oz)

SHAPES: Ball / Croquette / Two-ends / Drop

Optional Accessories: A wide variety of nozzles, molds, stamps, and other devices, such as: rissole stamp, square nozzle, triangular nozzle, star nozzle, special straight-cut mold, basket mold, sausage cutter, and much more. Check out the full range of Maxiform accessories.

Dough Hopper Capacity: 32l (8,4gal)

Filling Hopper Capacity: 12l (3,17gal)

Dimensions (W x L x H): 700 X 2220 X 1350mm (2ft 3.6″ x 7ft 3.4″ x 4ft 5.1″)

Eletricity: 0,91 kW (1,24HP) | 220V | Single-phase

Weight: 172Kg (379,2lbs)

We offer 1 year warranty* and technical support. Bralyx provides assistance for all machines.

¹ May vary depending on the type of dough, size, and shape of the product.

² The machine manufactures products up to 180g (depending on the type of dough, filling and size of the product). Larger products use the 220g kit (optional accessory).

HOURLY PRODUCTION¹:

- up to 5000 pcs (7 -30g / 0,24 –0,55oz)

- up to 1150 pcs (180 /220g /6,35/7,76oz)

PRODUCT SIZE²: from 7 to 220g (from 0,24oz to 7,74oz)

SHAPES: Ball / Croquette / Two-ends / Drop

Optional Accessories: A wide variety of nozzles, molds, stamps, and other devices, such as: rissole stamp, square nozzle, triangular nozzle, star nozzle, special straight-cut mold, basket mold, sausage cutter, and much more. Check out the full range of Maxiform accessories.

Dough Hopper Capacity: 32l (8,4gal)

Filling Hopper Capacity: 12l (3,17gal)

Dimensions (W x L x H): 700 X 2220 X 1350mm (2ft 3.6″ x 7ft 3.4″ x 4ft 5.1″)

Eletricity: 0,91 kW (1,24HP) | 220V | Single-phase

Weight: 172Kg (379,2lbs)

We offer 1 year warranty* and technical support. Bralyx provides assistance for all machines.

¹ May vary depending on the type of dough, size, and shape of the product.

² The machine manufactures products up to 180g (depending on the type of dough, filling and size of the product). Larger products use the 220g kit (optional accessory).

Machine-produced food

Complementary machines

Similar Products

Similar Products

✕

Bralyx Contact Center

Fill in the details to chat with our team!

Main Menu

Shopping Cart (0)

Account

Share

Facebook Pinterest Linkedin Whatsapp

Copy Link

[wcboost_compare_button][wcboost_wishlist_button]

Share this item